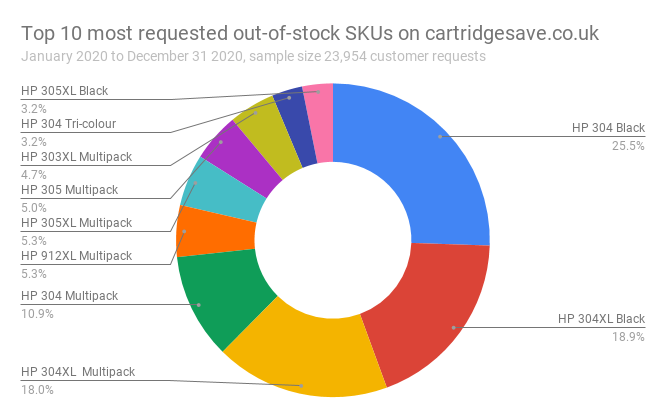

You might have recently been disappointed to find that your printer cartridge is currently out of stock. This has been affecting all manufacturers including HP, Canon and Epson, especially on ink cartridges like the HP 304 and 305.

Here are a few reasons why printers and printer cartridges are currently in short supply:

Unprecedented demand

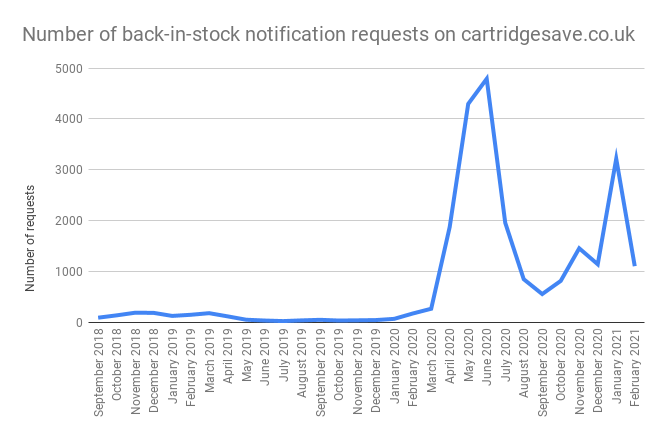

We are living in unusual times. The Covid pandemic has seen offices across the world closing their doors and billions of people working from home. This new way of working has led to a change in direction in the printing industry, away from commercial office printing, towards home printing. As a result, there has been a sudden increase in demand for home printers and the ink cartridges that feed them – something no one in the supply chain could have foreseen at the beginning of 2020.

A recent report by Deloitte stated that home printer sales grew by 15% in 2020. It said when the virus hit, millions of people “brought their laptops home in a bag… but left their printers behind!” Many manufacturers currently have back-orders of over one million units to satisfy and it will take time for them to upscale their production sufficiently to meet these requests. “We’ve been rushed off our feet trying to keep up with the spike that we saw, certainly at the beginning of lockdown,” Epson’s Alice Ramsden De Gómez recently told Wired.

And it’s not just the world of work that has changed. Schools have closed and homeschooling has become the new norm. Parents of primary school children in particular, are finding they need to print out several worksheets every week, often for multiple children, in order to stay on top of their learning. While educational facilities tend to have printers used to produce large numbers of copies, parents are using entry-level inkjets for their homeschooling needs.

Working from home and homeschooling are obvious areas where there has been an increase in demand for printing products but there have been other surprising ramifications for the industry. The pandemic has seen an increase in demand for packaged food and pharmaceuticals which all require printing. In addition, the massive growth in online shopping which Covid has created – up nearly 50% according to the Office of National Statistics – has led to an increase in people needing to print off return slips and shipping labels. This was not required when you could return an item to a store.

Factory lockdowns

The global pandemic has also affected the manufacture of printers and printer cartridges. National lockdowns, often for several months, in the likes of India, China and Malaysia have seen factories close and the production of printing components virtually grind to a halt. When factories reopened, the introduction of Covid-safe practices, such as additional cleaning, social distancing and employee absence for self-isolation, has meant that they have been slow to catch up to pre-pandemic levels of productivity and get through the backlog of orders.

Raw material sourcing

Sourcing the raw materials that are used in printers, ink and toner has also proved a challenge due to Covid. Lockdowns and social distancing at chemical plants have meant that many of the plastics and chemicals used in the printing industry have been in short supply. In particular, ethanol and n-propanol (used to make printing ink) have seen a surge in demand because they are also key ingredients in hand sanitisers and disinfectants.

Supplies have understandably been diverted into making these critical products, but this has been at the expense of other areas where they are also needed, such as the printing and packaging industry. The situation became so serious that the UK printing industry called on the UK government to ensure necessary supplies of ethanol, n-propanol and other raw materials were maintained so that the printing industry could fulfil its important role in producing food, medicines and essential packaging throughout the COVID-19 pandemic.

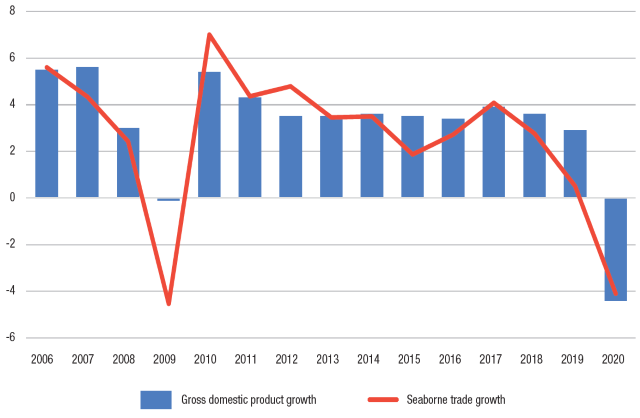

Sea freight reduction

Another knock-on effect of coronavirus is that sea freight has been significantly reduced. The Review of Maritime Transport 2020 revealed that global marine trade decreased by 4.1% in 2020 with cargo volumes plummeting.

“The outbreak came at a time when shipping companies are used to lower demand due to the Chinese New Year and had already planned for this,” BIMCO chief shipping analyst Peter Sand told Ship Technology Global magazine in March 2020. But when the Chinese New Year was extended and passengers on cruise ships started testing positive, Asian ports introduced screening procedures to stop the virus spread. This led to order delays and cancellations.

The next hit to sea freight came as populations were locked down. Non-essential shops closed, reducing international trade. This reduction in reciprocal trade led to a global metal container shortage as they were sat in ports instead of passing around the world. This has made it difficult for the printing industry to get its products from where they are made, predominantly in Asia, to the American and European markets where they are sold.

Brexit

Many printing manufacturers such as HP, have factories or warehouses in Europe and were adversely affected by the end of the Brexit transition period on 31st December 2020. As the UK and EU are no longer in a customs union, customs checks and other formalities now apply when these products are moved across the UK border. These can be time-consuming and add an extra bureaucratic burden on suppliers and lorry drivers. Brexit has slowed goods coming from these European warehouses by at least 48 hours, with many products getting stuck at customs for up to a week. In time, we expect these issues to be ironed out, but the new system is still being put in place, making the logistics of printing products increasingly difficult.

In conclusion, printer ink is out of stock because of unprecedented demand, factory lockdowns, shortage of ethanol, sea freight reduction and Brexit. If your desired item is out of stock, feel free to contact us about future availability or a possible replacement.